Collision repair for commercial vehicles like Mercedes-Benz is a precise, multi-step process requiring specialized equipment and skilled technicians due to their complex construction and safety features. Time frames are influenced by damage complexity, resource availability, and fleet schedules. Optimizing these frames is crucial for minimal downtime and business continuity in fleet operations; strategies include efficient workflows, staff training, and leveraging technology like digital imaging and CAD software for accurate assessment and swift repairs.

Collision repair time frames for fleet and commercial vehicles vary significantly due to unique operational demands. This article delves into the intricacies of collision repair processes specific to these vehicles, exploring key factors affecting repair speed. We’ll uncover strategies to optimize recovery time, focusing on efficient workflows and resource management. By understanding these dynamics, fleet managers can enhance overall operational efficiency and minimize downtime, crucial for maintaining commercial success in today’s competitive landscape.

- Understanding Collision Repair Processes for Commercial Vehicles

- Factors Affecting Repair Time in Fleet Operations

- Optimizing Recovery Time: Strategies for Efficient Repairs

Understanding Collision Repair Processes for Commercial Vehicles

Collision repair for commercial vehicles is a complex process that involves several intricate steps. Unlike personal vehicles, these trucks, buses, and vans often require specialized equipment and skilled technicians to handle their unique construction and safety features. The collision repair time frame for these larger vehicles can be significantly longer due to these factors.

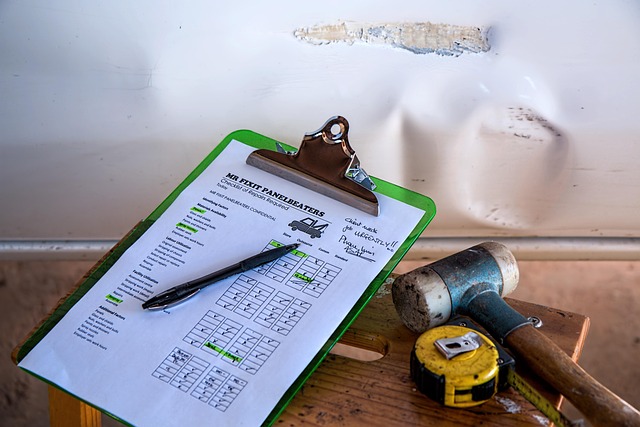

Understanding the specific needs of commercial vehicles like Mercedes-Benz repairs is crucial for auto body shops. This includes not just restoring structural integrity but also ensuring compliance with stringent safety regulations. Each step, from initial assessment and disassembly to panel replacement and refinishing, demands precision and attention to detail. The longer repair time frame reflects these considerations, aiming to deliver top-quality, safe, and reliable repairs for fleet operators and commercial vehicle owners.

Factors Affecting Repair Time in Fleet Operations

Several factors significantly influence the collision repair time frame for fleet and commercial vehicles. One of the primary considerations is the complexity of the damage. Severe collisions may require more extensive repairs, including replacement parts and multiple stages of labor, which can extend the overall turnaround time. The availability of specialized equipment and skilled technicians at the collision center or vehicle body shop is another critical aspect; limited resources might delay the repair process.

Additionally, fleet operations often involve tight schedules and strict maintenance deadlines, putting pressure on repair times. Coordination between various departments and vendors becomes essential to streamline the process efficiently. Effective communication and clear expectations can help manage these complexities, ensuring that vehicles are repaired within the desired timeframe while maintaining quality standards.

Optimizing Recovery Time: Strategies for Efficient Repairs

Optimizing recovery time is a key strategy for efficient collision repairs, especially for fleet and commercial vehicle operations where downtime can significantly impact business continuity. Efficient workflows, well-trained technicians, and specialized equipment play a crucial role in expediting repairs while maintaining high-quality standards. Implementing structured processes, such as streamlined estimating, inventory management systems, and coordinated parts procurement, helps to minimize delays caused by administrative tasks, part availability issues, and labor bottlenecks.

Furthermore, leveraging technology like digital imaging, computer-aided design (CAD) software, and automated body repair systems can dramatically enhance precision and speed. These tools enable technicians to accurately assess damage, plan repairs more effectively, and execute them with greater efficiency. Regular training on the latest techniques and technologies ensures that staff are equipped to handle a wide range of collision scenarios, further reducing overall repair time frames and contributing to faster vehicle recovery for fleet and commercial operations.

In conclusion, optimizing collision repair time frames for fleet and commercial vehicles is a strategic necessity. By understanding the intricate processes involved, identifying key factors that impact repair timelines, and implementing efficient strategies, businesses can significantly enhance their operational recovery times. These measures not only reduce downtime but also contribute to cost savings and improved customer satisfaction in the dynamic world of commercial vehicle maintenance.